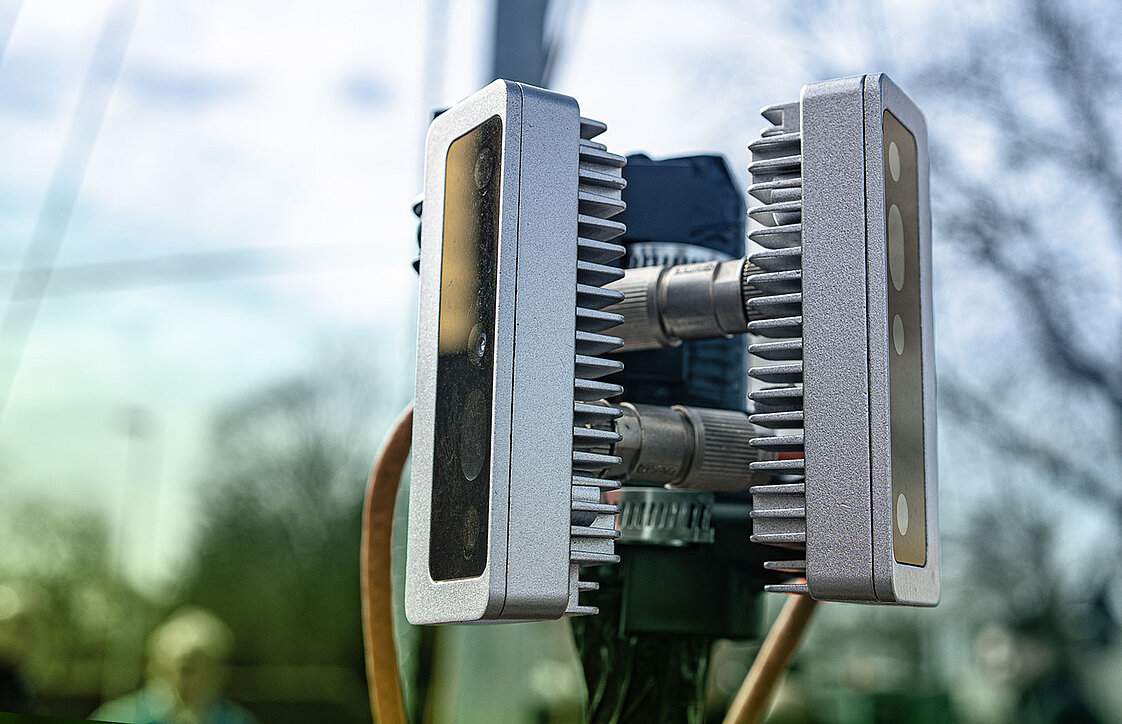

In a unique pilot project, we're developing remote crane control consoles at one of our sites. The goal is to future-proof the job of operating cranes and to prepare ourselves for partial autonomisation.

In the future, crane operators will need to be able to monitor and control more than one crane at a time, and they'll need to do this safely and using automation.